Arburg Plastic Freeforming (APF) and the Freeformer will be presented by Arburg in Hall 2, Stand 2-801 at the Rapid.Tech trade fair

Arburg Plastic Freeforming (APF) and the Freeformer will be presented by Arburg in Hall 2, Stand 2-801 at the Rapid.Tech trade fair and user convention from 20 to 22 June 2017 in Erfurt (Germany). The industrial additive manufacture of functional components from the original material Lexan 940 (PC), which is approved for the aerospace industry, will be demonstrated.

"Functional replacement parts, medical implants and functional spare parts are just three of the many areas for which our Freeformer and Arburg Plastic Freeforming are the ideal choice," explains Eberhard Lutz, Arburg's Director of Freeformer Sales in summary. "The new Arburg Prototyping Center with six Freeformers recently opened its doors at our headquarters in Lossburg and is now available for the manufacture of sample parts from qualified and certified original materials. This means that our APF experts can now respond even more promptly to customer inquiries and produce sample parts practically around the clock."

Functional parts made from qualified original materials

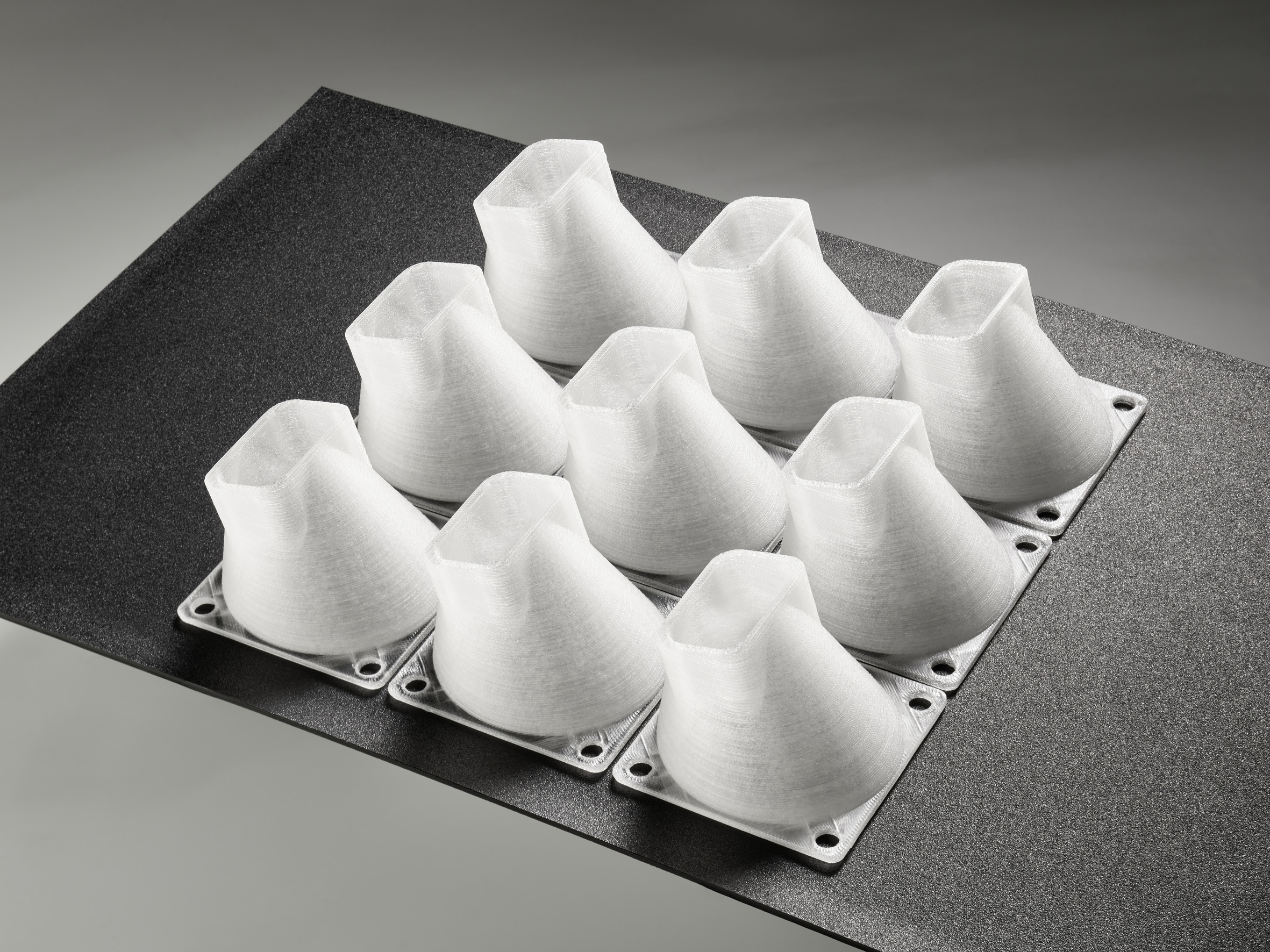

One major advantage of Arburg Plastics Freeforming (APF) is the option for processing the same qualified standard granulates as used for injection moulding. The Freeformer is equipped with two discharge units as standard. This enables it to process an additional component in order to manufacture a part in different colours, with special tactile qualities or as a hard/soft combination, for example. In order to implement complex geometries, support structures can be used as the second component. Air ducts made from the original material PC Lexan 940 authorised for the aerospace industry will be produced at the Rapid.Tech 2017. Small batches of nine functional components each will be produced in a build time of around 24 hours.

The advantages of the open system

As the Freeformer and APF are open systems, the process parameters can be specifically optimised for the relevant application. Arburg has already used many sample parts to show how many areas of application can be served with the Freeformer, including:

• individually adapted implants made from medical grade PLA that can be absorbed by the body after a defined period of time,

• flame-proof PC/ABS connectors for the electronics industry,

• assembly tools, grippers for automation and other equipment, e.g. from PA in combination with soft TPE,

• an articulated rope pulley, the housing and fastening hook of which are made from robust Bio-PA (Grilamid).

New support material from Arburg

In addition to the water-soluble support material Armat 11, Armat 21, which is soluble in sodium hydroxide, is also available from Arburg from May 2017 onwards. This support material, which is also used at the trade fair, can be processed with ease and is thermally stable. It has very good droplet formation and adhesion properties, as well as excellent edge definition in relation to the build material.

Individualisation of high-volume parts

Above and beyond the additive manufacture of one-off parts and small batches, high-volume parts can also be enhanced and customer wishes incorporated directly in the value chain by combining additive manufacturing, injection moulding and Industry 4.0 technologies.

For more information, please isit www.arburg.com